Low oil prices have led to the adoption of digitalization in the oil and gas industry, accelerating cybersecurity risks.

Advances in digitalization, such as smart engineering technology (SET), industrial IoT (IIoT) and big data, can bring many benefits as well as many weaknesses in cybersecurity.

Benefits include:

- Reduce construction costs and eliminate waste materials through automated chains, thereby helping to improve profits.

- Enables faster and more effective decision making, thereby improving competitiveness.

- Improve product quality and reduce quality risks.

- Accelerating the deployment of digitalized tools and processes in oil and gas companies, thereby providing the opportunity to radically change business models and move towards important organizational changes.

Some potential weaknesses include:

- There is significant financial risk in the discovery phase, resulting in the data found being exposed, destroyed or manipulated.

- Vulnerable to risk and loss in environmental disasters and/or lives due to attacks targeting the oil well drilling process and technology.

- Security weaknesses in the design and construction of new facilities in sub-industries.

- Create new business relationships and joint ventures with suppliers or other third parties with weak security systems.

- Using insecure data storage or connections can increase the likelihood of falling prey to espionage, leading to financial impacts as well as loss of global competitive advantages.

Top questions companies should ask themselves:

- If you were currently under attack, would you be able to recognize it?

- What would you be able to do if you were attacked?

- How well do you know the microcosm of the IIoT/operational technology (OT) technology assets the company must protect?

- Is your business capable of operating without IIoT/OT support?

- How important is the IIoT environment to the business value of the product?

- What is the biggest cyber risk coming from your primary production environment?

- How do you ensure security and resilience in an era of increased data ingestion from multiple sources?

- How well do you know the limits of the environment your company needs to protect?

- Is the configuration of your IIoT/OT devices secure (backups, audits, offsite storage, etc.)?

How the age of digitalization and IIoT technology changes the threat landscape

The digital revolution and IIoT bring many great benefits to the oil and gas industry. However, they create many openings for new cybersecurity risks that we need to pay attention to immediately.

The Global Security Intelligence Survey (GISS) found that 57% of oil and gas industry respondents have recently experienced a serious cybersecurity incident. Similarly, a report from the World Energy Commission in September 2016 found that cybersecurity is a top issue in the energy industry, especially in North America and Europe, where Most developed facilities.

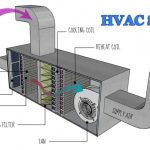

OT environments inherently focus on ensuring high availability without paying much attention to security and integrity, so the digitalization and modernization process has made them susceptible to risks. Cyber security at the present time. Continuing to separate IT and OT environments no longer seems practical or cost-effective. Indeed, to get the best benefits from digitalization and smart technology, it is necessary to combine the above two environments. These changes are also being driven by the advent of new technologies such as IIoT and big data analytics.

The quality and safety of operations depend largely on the network

The convergence of IT and OT environments has created new cyber-physical risks.

“Cyber-cyber-physical systems, or “smart” systems, are interactive networks of physical and computational components,” says the National Institute of Standards and Technology (NIST). These systems will provide the foundation for our critical infrastructure, form the basis for future smart devices, and improve the quality of many aspects of life.”

New risks gradually emerge as networked terminals such as unmanned vehicles [EM1], smart sensors, handheld terminals, and industrial routers are produced and distributed without installing baseline network security protection.

As more and more devices become connected, the risk of intrusion increases.

Today, cyber-physical risks are not being detected, monitored and managed effectively – so how can these risks be reduced? This, along with the frequency of new technology distribution as well as the digitalization of production chains, proves that this is the right time to act. If cyber-physical systems are attacked, they could lead to dire consequences, leading to the loss of critical national infrastructure services to the public, and worse, leading to loss of life due to security failures.

An example of this problem can be easily found in unmanned vehicles (such as drones or driverless vehicles). Similar attacks in the oil and gas industry have the potential to result in damage to control systems, equipment and networks. They also bring many risks to the entire supply chain and affect operations in the local area. These are the core points of cyber-physical cybersecurity risks.

Implement secure and reliable digital operations processes

To be able to properly protect an organization’s processes and assets, it is necessary to establish a strategy for the organization to deal with cyber-physical security risks. A good cybersecurity strategy can lead to digital transformation by:

- Reduce safety and operational risks through managing and monitoring cyber-physical risks and new technologies.

- Accelerating the digitalization trend, through the introduction of a secure and tightly regulated cyber environment where new processes and technologies can be introduced to everyone.

- Unlock the potential of technology innovation by understanding the IT, OT and IioT asset landscape as well as the threats and risks that can impact uptime and integrity.

- Create resilient technology platforms for sites and organizational networks that can predict attacks or outages before they happen.

Oil and gas companies are currently in different stages of their digital transformation journey. Understanding today’s cyber-physical security risk landscape as well as the dangers posed by IoT and new technologies is critical to organizations planning for future success. Reliable and resilient area operations. A clear understanding of the benefits of taking a proactive approach to security today is also important to avoid serious weaknesses later. Such approaches also help reduce the risk of delays or problems once digital transformation projects are underway.

Two smart ways to invest in cybersecurity

- Benchmark security standards with similar companies

- Ensure security spending by looking at the security of protected values and ensuring the resiliency of industrial operations.

The more value we create from interconnected cyber-physical systems, the more attention we must pay to protecting them.

Three best things to do now

To reduce your company’s safety and reliability risks, consider doing the following:

Before adopting new “connected” technologies, ask your supplier to prove the product’s security level: Today’s devices are always delivered with security flaws. Therefore, ensuring the security system is carefully installed before distribution will protect the company from IioT endpoint threats and the impacts on safety, reputation and economics later on. .

Recognize cyber-physical risk domains, and add them to risk management tools immediately: Your company’s risk footprint is growing in parallel with every connected technology you implement, which could affect the safety and reliability of your company and employees. Interactions with customers have shown that many companies are unaware of the need for cybersecurity vulnerability testing, which is extremely important, especially for the connection between OT and IT systems. . The lack of cyber reporting on cyber security attacks in industry is another factor that complicates knowledge about the size and nature of various types of risks.

Applying cybersecurity to the digitalization strategy for operational processes: Because the more we digitize, the more cyber risk footprints increase. Ensuring it is part of the digital design process will allow us to apply more technology without increasing operational risks. The US Department of Internal Security has confirmed that the oil and gas industry is the industry most exposed to attacks.

Vina Aspire is a consulting company, providing IT solutions and services, network security, information security & safety in Vietnam. Vina Aspire’s team includes skilled, qualified, experienced and reputable experts and collaborators, along with major domestic and foreign investors and partners to join hands in building.

Businesses and organizations wishing to contact Vina Aspire Company with the following information:

Email: info@vina-aspire.com | Website: www.vina-aspire.com

Tel: +84 944 004 666 | Fax: +84 28 3535 0668

![]()

Vina Aspire – Vững bảo mật, trọn niềm tin