The internet of things trend in factories makes them more vulnerable to cyber attacks.

–

9 factories in 6 countries. That is the scale of the attack on Honda this week and is considered the work of ransomware silently installed on the Japanese car company’s internal network, disrupting essential systems. , production lines globally.

The attack clearly shows the risks companies face as they gradually transition to the Internet of Things (IoT). Many offices and factories apply smart technology to support employees working remotely during the epidemic. But it also opens the door to more cyber attacks.

According to Mr. Toshihiro Fukuda from Japanese company JT Engineering, some companies have begun to control factory operations remotely to deal with the virus. The risks can only increase.

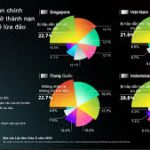

According to security software provider McAfee, cyberattacks against manufacturers increased sevenfold from January to April this year. Financial losses due to data breaches in the first quarter of this year amounted to 8.4 billion USD, an increase of 270% over the same period in 2019.

Most of Honda’s facilities have resumed operations, but a factory in the US and Brazil is still closed. Operations in Japan, Italy, Türkiye and the UK were also affected.

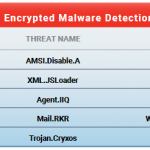

Essentially, ransomware blocks connections to the computer it infects, forcing victims to pay a ransom to unlock the device. It can happen silently, spreading to other machines operating on the same network.

In January 2020, ransomware caused Belgian textile machinery manufacturer Picanol to cease operations in Europe and China. British steel company BlueScope was also attacked in May 2020.

Other businesses without production activities are also victims. Healthcare company Fresenius was attacked with ransomware last month, interfering with dialysis machines.

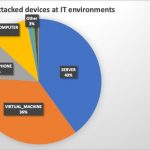

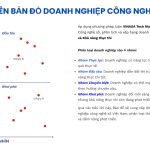

Many attacks are exacerbated by IoT. Companies connect more devices to the Internet than ever before so they can regulate production and control remotely. That means more departments are vulnerable to cyber attacks. Hackers use network analysis tools and other measures to search for vulnerabilities in factories.

Meanwhile, according to KPMG, 26% of companies surveyed do not have a security monitoring department in factory management systems.

Equipment longevity is another concern. According to research published in 2019 by the Japan Machinery Federation, more than 60% of domestically produced equipment is at least 10 years old. Many are controlled by computers running old operating systems, no longer supported by their manufacturers, making them especially vulnerable to external attacks.

Vina Aspire Co., Ltd | The unit specializes in consulting and providing solutions on network security, confidentiality, and information security

Source: Vietnamnet (According to Nikkei)

VINA ASPIRE UNVEILS OFFICIAL BRAND AMBASSADOR MIRA – INTELLIGENCE. ELEGANCE. TECHNOLOGY.

VINA ASPIRE UNVEILS OFFICIAL BRAND AMBASSADOR MIRA – INTELLIGENCE. ELEGANCE. TECHNOLOGY.  A New Chapter Begins In an era defined by digital transformation, where cybersecurity, artificial intelligence, and enterprise…

A New Chapter Begins In an era defined by digital transformation, where cybersecurity, artificial intelligence, and enterprise…

…

…